Top 2025 Trends in Shrink Sleeves: Innovations and Applications Explained

As we look ahead to the emerging trends in the packaging industry, shrink sleeves are poised to play a pivotal role in enhancing product presentation and functionality. According to industry expert Dr. Emily Hartman, a renowned leader in flexible packaging solutions, "Shrink sleeves are not just a packaging option; they are an innovative tool that redefines how products engage with consumers." This insight encapsulates the growing significance of shrink sleeves in various markets, from food and beverages to pharmaceuticals.

The evolution of shrink sleeves is marked by innovative designs, improved materials, and advanced printing techniques. As trends shift towards sustainability and consumer preferences evolve, manufacturers are increasingly leveraging shrink sleeves to meet these demands. This article explores the top trends of 2025, examining how advancements in shrink sleeve technology are set to enhance product appeal and functionality while addressing sustainability concerns.

With a focus on new applications and technological breakthroughs, the future of shrink sleeves looks promising. From increased graphic capabilities to eco-friendly materials, these innovations are not only transforming packaging aesthetics but also driving operational efficiencies. Join us as we delve into the exciting landscape of shrink sleeves and their transformative potential for the packaging industry in 2025 and beyond.

Overview of Shrink Sleeve Technology Advancements in 2025

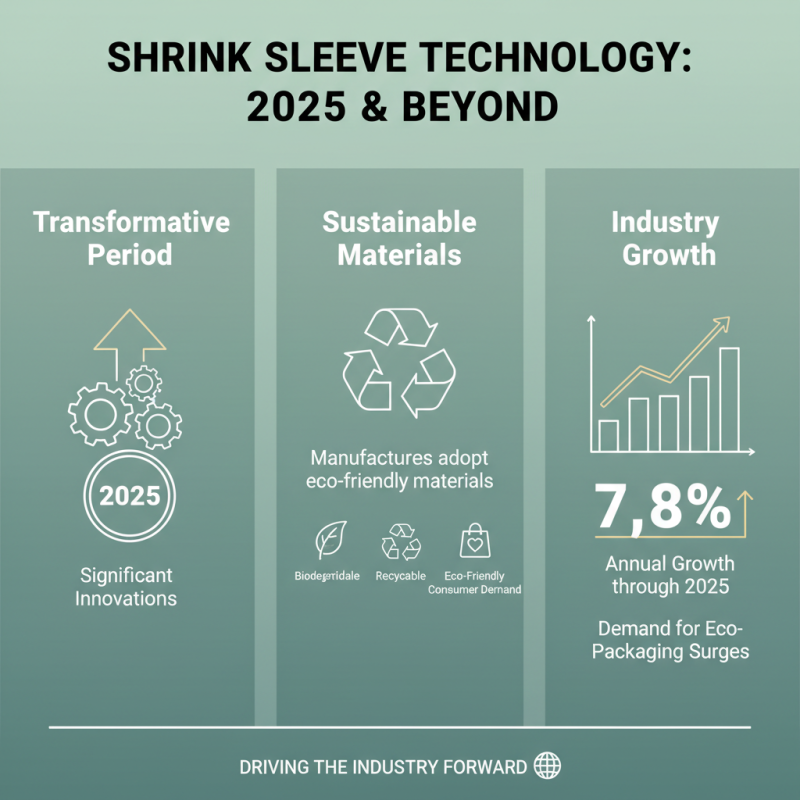

The year 2025 marks a transformative period for shrink sleeve technology, showcasing significant innovations and applications that are driving the industry forward. One of the major advancements is the integration of sustainable materials into the production of shrink sleeves. According to a recent industry report, the demand for eco-friendly packaging solutions has surged, with a projected growth rate of 7.8% annually through 2025. Manufacturers are increasingly adopting biodegradable and recyclable materials, catering to the rising consumer preference for sustainable products.

Another noteworthy trend is the enhancement of printing technology used in shrink sleeves. With advancements in flexographic printing and digital printing technologies, brands are able to achieve high-quality graphics and vibrant colors that enhance shelf appeal. A study from the Market Research Institute indicates that the digital printing segment in the shrink sleeve industry is expected to account for over 30% of the market share by 2025, enabling shorter production runs and greater customization options for brands. Additionally, improvements in adhesion and shrinkage capabilities have resulted in better performance under various environmental conditions, ensuring that products maintain their aesthetic and functional integrity throughout their lifecycle.

Key Innovations Driving the Future of Shrink Sleeves

The shrink sleeve label market is witnessing transformative advancements that are set to influence its trajectory through 2025 and beyond. Innovations in material science are leading the charge, with polyethylene and polyolefin materials becoming increasingly popular due to their remarkable formability and durability. According to a recent report by Smithers Pira, the global shrink sleeve label market is projected to reach approximately $14 billion by 2025, fueled by growth in sectors such as food and beverage, personal care, and pharmaceuticals, which increasingly demand customizable and eye-catching packaging solutions.

Another critical innovation shaping the future of shrink sleeves is the development of eco-friendly and sustainable materials. With rising consumer awareness around environmental issues, manufacturers are prioritizing biodegradable and recyclable materials. Reports from the Packaging Association indicate that nearly 70% of consumers are more inclined to purchase products with sustainable packaging. Furthermore, advancements in printing technology, such as digital printing, are enabling brands to create vibrant, high-resolution graphics that enhance shelf appeal and consumer engagement. As brands continue to focus on sustainability and aesthetic differentiation, these trends will likely solidify the role of shrink sleeves as a pivotal player in the packaging landscape.

Emerging Applications of Shrink Sleeves Across Various Industries

Shrink sleeves have emerged as a versatile solution across numerous industries, transcending traditional packaging and labeling applications. One of the key innovations driving this trend is the introduction of eco-friendly materials, which align with the growing demand for sustainable practices. Companies in the food and beverage sector are particularly benefiting from these advancements, as shrink sleeves provide tamper-evident packaging that enhances product safety while also being recyclable. This shift not only appeals to environmentally conscious consumers but also helps brands reduce their carbon footprint.

In the pharmaceutical and healthcare industries, shrink sleeves are gaining traction for their ability to accommodate complex shapes and sizes. Their stretchy nature allows for secure labeling of various packaging formats, ensuring that critical information, such as dosage and expiration dates, remains visible and intact. These sleeves also contribute to counterfeiting prevention by incorporating unique designs or security features, thus safeguarding public health. Moreover, the introduction of smart technology into shrink sleeves—such as QR codes—enables customers to access information instantly, further revolutionizing their application in this vital sector.

Sustainability Trends Impacting Shrink Sleeve Materials and Production

Sustainability is increasingly shaping the shrink sleeve market as manufacturers pivot towards eco-friendly materials and production processes. According to a report by Smithers Pira, the global shrink sleeve market is expected to reach a value of $3.57 billion by 2025, with a significant push towards sustainable practices. This shift is driven by consumer demands for more environmentally friendly packaging solutions, with 72% of consumers indicating a preference for brands that prioritize sustainability. As a result, producers are investing in bio-based polymers and recyclable materials to reduce the environmental impact of shrink sleeves.

The adoption of sustainable materials, such as poly lactic acid (PLA) and post-consumer recycled (PCR) content, is gaining momentum. Industry research suggests that using PLA can reduce greenhouse gas emissions by up to 80% compared to traditional petroleum-based plastics. Additionally, advancements in production technologies, such as energy-efficient manufacturing processes, are further enhancing the sustainability profile of shrink sleeves. This aligns with the broader trend seen across packaging sectors, where companies are not only driven to meet regulatory standards but are also responding to the growing consumer expectation for products that reflect sustainability values. The integration of these innovations signifies a pivotal moment in the shrink sleeve industry, where environmental responsibility and product performance coexist.

Top 2025 Trends in Shrink Sleeves: Innovations and Applications

Market Trends and Consumer Preferences in Shrink Sleeve Designs

Shrink sleeves have gained traction in the packaging industry, driven by evolving market trends and shifting consumer preferences. Today, consumers are seeking more engaging and visually appealing packaging options that enhance the overall brand experience. This shift has led to a surge in demand for shrink sleeve designs that not only offer protection but also showcase vibrant graphics and unique textures. The ability to wrap around irregular shapes and provide 360-degree coverage has made shrink sleeves a preferred choice among manufacturers looking to differentiate their products on retail shelves.

Moreover, sustainability is rapidly becoming a key consideration for consumers when choosing products. Eco-friendly materials and recyclable options are increasingly influencing purchasing decisions, prompting brands to innovate their shrink sleeve solutions. The integration of biodegradable films and the reduction of plastic waste are initiatives that resonate well with today's environmentally conscious shoppers. As companies strive to align their packaging with consumer values, the trend towards sustainable shrink sleeve designs is expected to grow, ultimately shaping the future of product packaging in various sectors.

Top 2025 Trends in Shrink Sleeves: Innovations and Applications Explained

| Trend | Description | Application Area | Consumer Preference | Market Impact |

|---|---|---|---|---|

| Eco-Friendly Materials | Increase in demand for biodegradable and recyclable materials in shrink sleeves. | Food and Beverage Packaging | Higher preference for sustainable packaging solutions among consumers. | Positive impact on brand image and market competitiveness. |

| Digital Printing Technology | Advancements in digital printing for customized and small batch designs. | Personal Care Products | Consumers favor unique and personalized packaging experiences. | Increased brand differentiation and customer engagement. |

| Smart Packaging | Integration of QR codes and NFC technology for interactive packaging. | Electronics and Luxury Goods | Consumers seek enhanced product information and interactive features. | Greater consumer engagement and improved product traceability. |

| Enhanced Graphics and Visual Appeal | Use of vibrant colors and 3D effects to improve package appearance. | Beverage Industry | Consumers are drawn to visually appealing packaging. | Higher shelf visibility leading to increased sales. |

| Tamper-Evident Features | Incorporating seals to enhance product safety and consumer trust. | Pharmaceuticals and Food Products | Consumers prioritize safety and security in product packaging. | Increased consumer confidence and reduced product recalls. |

Related Posts

-

Discover the Future of Packaging: Top 5 Shrink Sleeves Trends in 2025

-

Top 5 Innovative Carton Packaging Solutions for Sustainable Business Growth

-

Why Business Packaging Matters for Success: Key Benefits and Strategies

-

2025 Top 10 Innovations in Corrugated Packaging for Sustainable Solutions

-

Ultimate Guide to Corrugated Box Tips for Effective Packing and Shipping

-

How to Choose the Best Paperboard Packaging for Your Products