How to Choose the Best Corrugated Box for Your Shipping Needs in 2025

In the ever-evolving landscape of shipping and logistics, the corrugated box stands as a quintessential component that ensures the safe transit of goods. As we approach 2025, businesses must refine their shipping strategies to accommodate growing demands and sustainability concerns. This necessitates a thoughtful selection of the best corrugated box, which not only protects products during transit but also aligns with environmental standards and enhances operational efficiency.

Choosing the right corrugated box involves evaluating multiple factors, including size, durability, and customizability. Specific shipping requirements vary greatly across different industries, making it vital for companies to understand their unique needs. Whether shipping fragile items or bulk products, selecting an appropriate corrugated box can mitigate risks associated with damage and returns, ultimately contributing to customer satisfaction.

With advancements in packaging technology and a heightened awareness of sustainability, the next few years will present new opportunities and challenges in the realm of corrugated boxes. By staying informed about trends and innovations, businesses can make more informed decisions that not only fulfill current shipping needs but also prepare for future demands in a competitive market.

Factors to Consider When Selecting Corrugated Boxes for Shipping

When selecting corrugated boxes for your shipping needs in 2025, several critical factors must be considered to ensure that you choose the most effective packaging solution. First, the strength and durability of the box are paramount, especially for heavy or fragile items. According to the Fibre Box Association, the ECT (Edge Crush Test) rating is a vital measure of a box's strength—the higher the ECT rating, the better the box can withstand the stacking and pressure during shipping. Boxes with a minimum of 32 ECT are often recommended for standard shipping, while those carrying heavier loads should seek boxes with 44 ECT or greater.

Another essential factor is the box's size and shape, as optimizing space can reduce shipping costs and minimize environmental impact. The Packaging Industry Association highlights that using the correct box dimensions reduces void fill materials and improves supply chain efficiency. Furthermore, consider the box's recyclability and sustainability, as customers increasingly prefer eco-friendly options. A study by Smithers Pira indicates that the demand for sustainable packaging is projected to grow by 5% annually over the next five years, emphasizing the importance of selecting corrugated boxes made from recycled materials or those that can be easily recycled. An informed choice will not only enhance shipping efficiency but also align with consumer preferences in a competitive marketplace.

Types of Corrugated Boxes Suitable for Different Shipping Needs

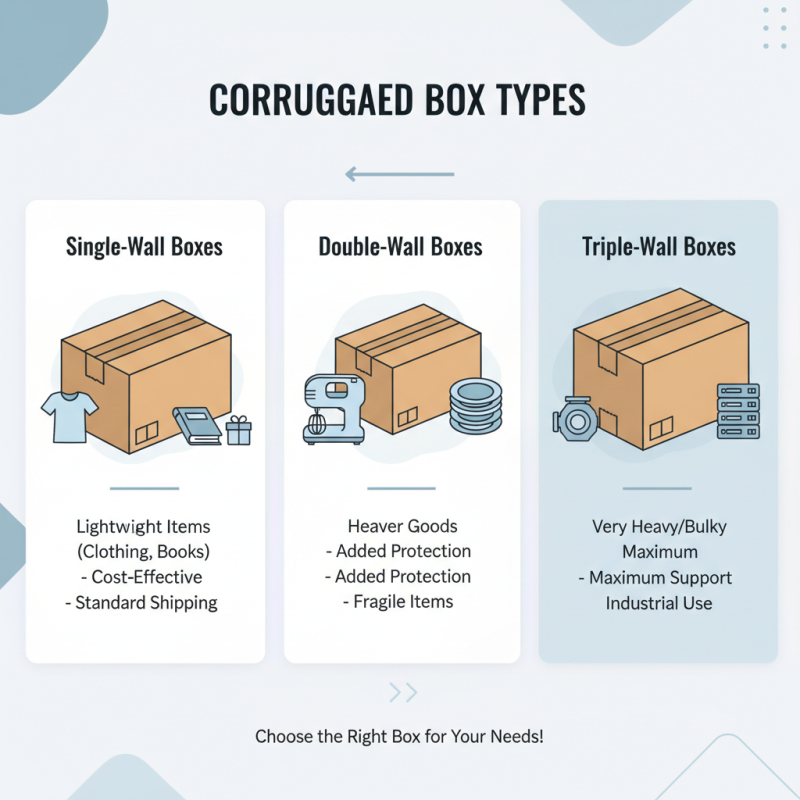

When it comes to selecting the right corrugated box for shipping, understanding the different types available is crucial to meet your specific needs. Corrugated boxes can generally be categorized into several types based on their structure and intended use. For instance, single-wall boxes are the most common and are perfect for lightweight items such as clothing or books. They provide sufficient protection while being cost-effective for standard shipping tasks.

For heavier or more fragile items, double-wall boxes offer extra durability and cushioning. They are designed with two layers of fluting and are ideal for shipping electronic equipment or glassware, where added strength is essential. Additionally, specialized options like padded mailers and die-cut boxes can cater to unique shipping requirements. Padded mailers, often lined with bubble wrap, provide added protection for delicate objects, while die-cut boxes can be customized to fit specific products, ensuring they do not shift during transit. As online shopping continues to evolve, selecting the appropriate corrugated box type will enhance both safety and efficiency in your shipping process.

Assessing Durability and Strength Requirements for Your Shipments

When selecting the best corrugated box for your shipping needs in 2025, understanding the durability and strength requirements is essential. The integrity of your packaging directly impacts the safety of the products during transit. Begin by assessing the weight and fragility of the items you plan to ship. Heavier and more delicate items often require boxes with a higher burst strength and stacking capability to withstand pressure, especially in crowded shipping environments.

Additionally, evaluate the environmental conditions your packages will encounter. Factors such as humidity, temperature variations, and exposure to moisture can significantly affect the performance of corrugated boxes. Ensure that the chosen boxes are constructed from materials designed to handle these conditions, often opting for moisture-resistant options for vulnerable items.

Adapting to these aspects will not only protect your shipments but also contribute to customer satisfaction and reduce returns due to damage during shipping.

Understanding Environmental Impact and Recyclability of Corrugated Boxes

When selecting a corrugated box for your shipping needs in 2025, it’s crucial to consider the environmental impact and recyclability of the materials. Corrugated boxes are widely appreciated for their strength and lightweight properties, but their sustainability also determines their viability in today’s eco-conscious market. The production process of these boxes often involves significant energy consumption and resource use. Therefore, opting for boxes made from recycled paper or sustainably sourced materials can significantly reduce your carbon footprint.

Tips for ensuring that your corrugated boxes are eco-friendly include checking for certifications like FSC (Forest Stewardship Council) that guarantee sustainable sourcing. Additionally, consider the thickness and structure of the box. Thicker boxes may offer more durability, but lightweight options contribute to lower transport emissions. Furthermore, always look into the recyclability of the materials. Boxes marked with recycling symbols or guidance on proper disposal ensure that you are making environmentally responsible choices.

Another essential point is to assess the potential for reuse. Choosing boxes that can withstand multiple uses not only saves money but also fosters a circular economy. Explore options for dual-purpose boxes that can be repurposed after their initial shipping function, as this contributes to reducing waste and promotes sustainability across supply chains. By prioritizing these factors, you can select corrugated boxes that align with both your shipping needs and environmental responsibilities.

How to Choose the Best Corrugated Box for Your Shipping Needs in 2025 - Understanding Environmental Impact and Recyclability of Corrugated Boxes

| Box Type | Strength Rating (ECT) | Weight Capacity (lbs) | Recyclability (%) | Environmental Impact Score (1-10) |

|---|---|---|---|---|

| Single Wall | 32 ECT | 50 | 80 | 5 |

| Double Wall | 44 ECT | 75 | 90 | 6 |

| Triple Wall | 65 ECT | 100 | 95 | 7 |

| Die-Cut Boxes | 32 ECT | 40 | 85 | 4 |

| Heavy-Duty Boxes | 60 ECT | 120 | 80 | 5 |

Cost-Effective Strategies for Sourcing the Right Corrugated Packaging

When sourcing corrugated packaging for shipping needs in 2025, cost-effectiveness is critical. A recent report from Smithers Pira forecasts that the global demand for corrugated packaging will grow at a compound annual growth rate (CAGR) of 4.4%, reaching $290 billion by 2024. This growing demand places significant pressure on businesses to find affordable yet reliable solutions. To keep costs down, companies should consider consolidating their orders to leverage bulk purchasing discounts and explore local suppliers to minimize freight costs. By evaluating the total landed cost, businesses can better align their sourcing strategies with budgetary constraints.

Another effective strategy is to embrace sustainable materials, which are increasingly sought after by consumers and regulatory bodies alike. According to the Paper and Packaging Board, 73% of consumers are willing to pay more for sustainable packaging options. By investing in eco-friendly corrugated boxes made from recycled materials, companies not only cater to consumer preferences but can also qualify for tax credits and incentives tied to sustainability initiatives. Furthermore, many eco-friendly options are competitive in price, making them a viable choice for long-term savings and brand differentiation. In 2025, aligning packaging strategies with both cost-efficiency and environmental responsibility will be key to staying competitive in the shipping industry.

Related Posts

-

2025 Top 10 Innovations in Corrugated Packaging for Sustainable Solutions

-

2025 Top Corrugated Packaging Trends: Optimize Sustainability and Efficiency for a $300 Billion Industry

-

Ultimate Guide to Corrugated Box Tips for Effective Packing and Shipping

-

Top 5 Film Packaging Solutions You Need to Know for Your Business

-

Discover the Future of Packaging: Top 5 Shrink Sleeves Trends in 2025

-

How to Choose the Perfect Packaging Labels for Your Products in 2023